- Value Design Ltd

- Services

- Projects

-

Finite Element Analysis

- Introduction to Basic FEA

- Units

- Co-ordinate Systems

- FEA Procedure

- Defining Objectives

- Stress Concentration

- Geometry import / clean up

- Meshing

- Material Properties

- Boundary Conditions

- Solvers

- Investigating FEA Results

- Reporting

- Stress Theories

- Cantilever Beam Worked Example

- Pressure Vessel Worked Example

- Shaft in Torsion Worked Example

- Buckling Worked Example

- Bearing (Contact) Worked Example

- Non Linear Material Worked Example

- Portal Frame Worked Example

- BLOG

- FAQ

- CONTACT

|

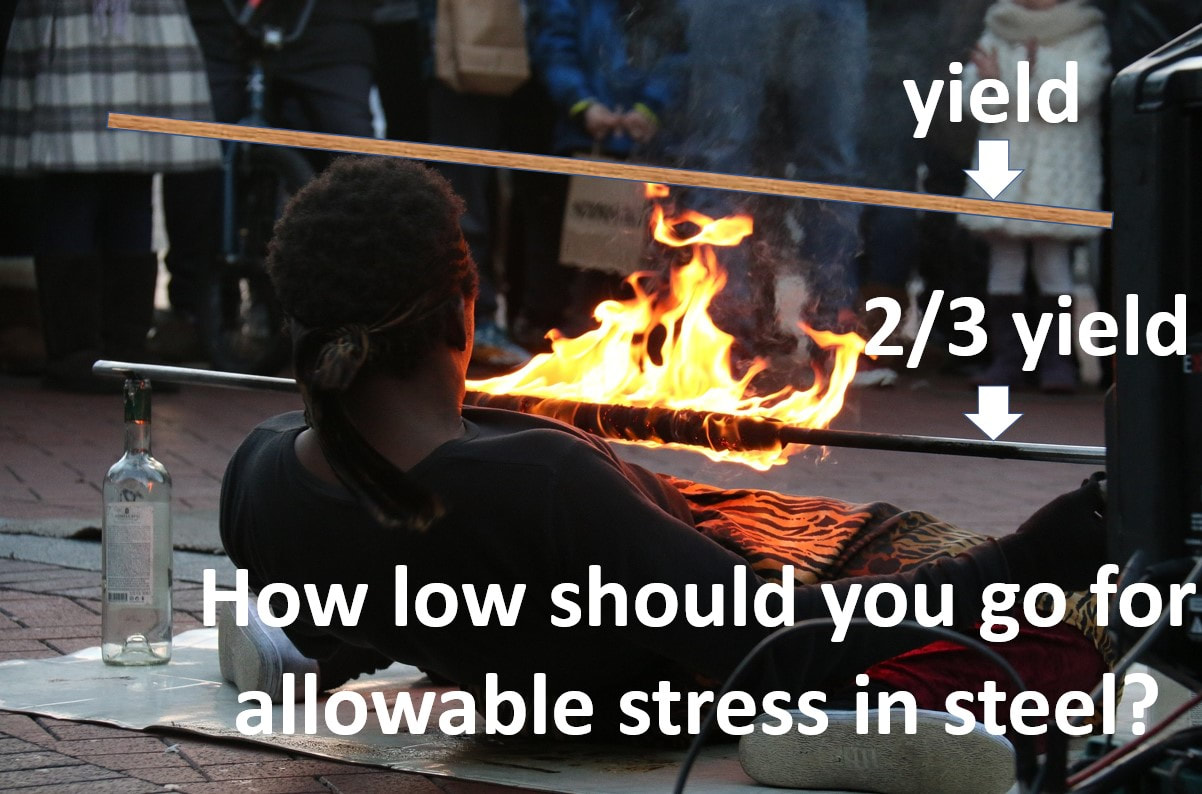

I posted this question as a poll on LinkedIn. It's a very simple question but the answer is not so simple.

We all have our reasons and I don’t think there is only one answer but here are my thoughts.

0 Comments

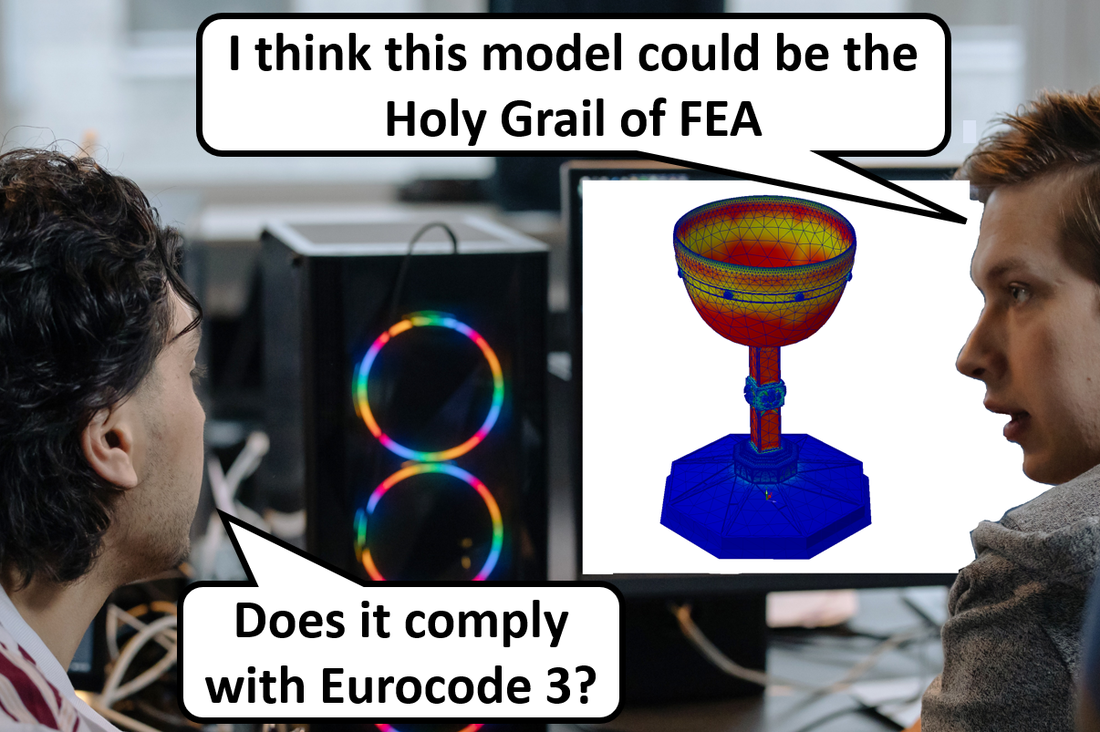

The Holy Grail is a cup and is generally accepted as mythic, but some believe it is more than just a figment of medieval literature.

Some believe the holy grail provides eternal youth, can heal all wounds and grant everlasting happiness. The Holy Grail is often used to describe something that is sought after and very hard to attain. My first thought was, if I found everlasting youth, I could be doing FEA for an eternity, so that put me off a bit. I’ve been using FEA for 25 years; I worked in many industry sectors with different software for numerous companies.

I’m working towards becoming an expert but I’m not there yet because there’s stuff I still need to learn. You see becoming an expert in FEA is like becoming an expert in mechanical engineering. We recently had our first work experience student.

Brandon is from Ecclesfield School and has ambitions to be an engineer (or a pilot) so we gave him the opportunity to work on a project for us. The project was a 3 tonne lifting beam, 6m long that was designed to BS EN 13155. Not everything is as it seems.

There are lots people out there telling half-truths and whole lies but did you know your FEA software is also doing this? Meet Max, the newest addition to the team.

There was a short paws in his career due to being on fur-lough but he was looking for a new roll. Hex and Tet are what you call frenemies, they are friends but are secretly jealous of each other and green with envy.

It was Saturday night and their boyfriends were watching football, so they decided to go on a girl’s night out. There are so many reasons engineering components break, I've seen quite a few and here is my top ten list. There must be many others that I've missed. I've always said that the best way to learn about engineering and in particular finite element analysis, is to study components that have already broken.

Those were the days! When we had 3 TV channels, the remote control was a broom handle and no one had a mobile phone. Kids rode their BMX bikes on the pavement, all wearing their Parka coats with hoods over their heads and the coat flapping behind them like a Batman cape.

Times have changed and things have moved on in the world and in engineering design. The days of over designing components are long gone, engineers are using tools like CAD, CAE, FEA and CFD to make lighter, stronger and more durable products. Here are my favourite top ten tips for designing durable components. Finite Element Analysis (FEA) is a very good tool for providing useful insight to the strength and durability of mechanical components and large structures. It’s often integrated into CAD and anyone can do it.

Learning to operate FEA software to check if components are the correct thickness or size is easy. Or is it?……… The answer is yes and no. It is easy to run analysis models and find stress levels but a bit harder to get it right first time. I get a lot of enquiries from clients to fix components that have broken because the FEA was not done properly. Embracing failure is the best way to learn from your own mistakes and those of others. Here is list of common reasons FEA Analysis goes bad! |

AuthorChris Hall Categories

All

Archives

May 2023

|

- Value Design Ltd

- Services

- Projects

-

Finite Element Analysis

- Introduction to Basic FEA

- Units

- Co-ordinate Systems

- FEA Procedure

- Defining Objectives

- Stress Concentration

- Geometry import / clean up

- Meshing

- Material Properties

- Boundary Conditions

- Solvers

- Investigating FEA Results

- Reporting

- Stress Theories

- Cantilever Beam Worked Example

- Pressure Vessel Worked Example

- Shaft in Torsion Worked Example

- Buckling Worked Example

- Bearing (Contact) Worked Example

- Non Linear Material Worked Example

- Portal Frame Worked Example

- BLOG

- FAQ

- CONTACT