- Value Design Ltd

- Services

- Projects

-

Finite Element Analysis

- Introduction to Basic FEA

- Units

- Co-ordinate Systems

- FEA Procedure

- Defining Objectives

- Stress Concentration

- Geometry import / clean up

- Meshing

- Material Properties

- Boundary Conditions

- Solvers

- Investigating FEA Results

- Reporting

- Stress Theories

- Cantilever Beam Worked Example

- Pressure Vessel Worked Example

- Shaft in Torsion Worked Example

- Buckling Worked Example

- Bearing (Contact) Worked Example

- Non Linear Material Worked Example

- Portal Frame Worked Example

- BLOG

- FAQ

- CONTACT

|

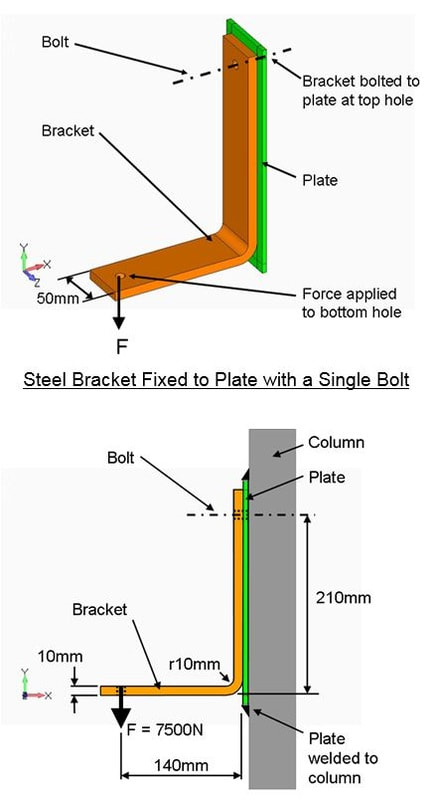

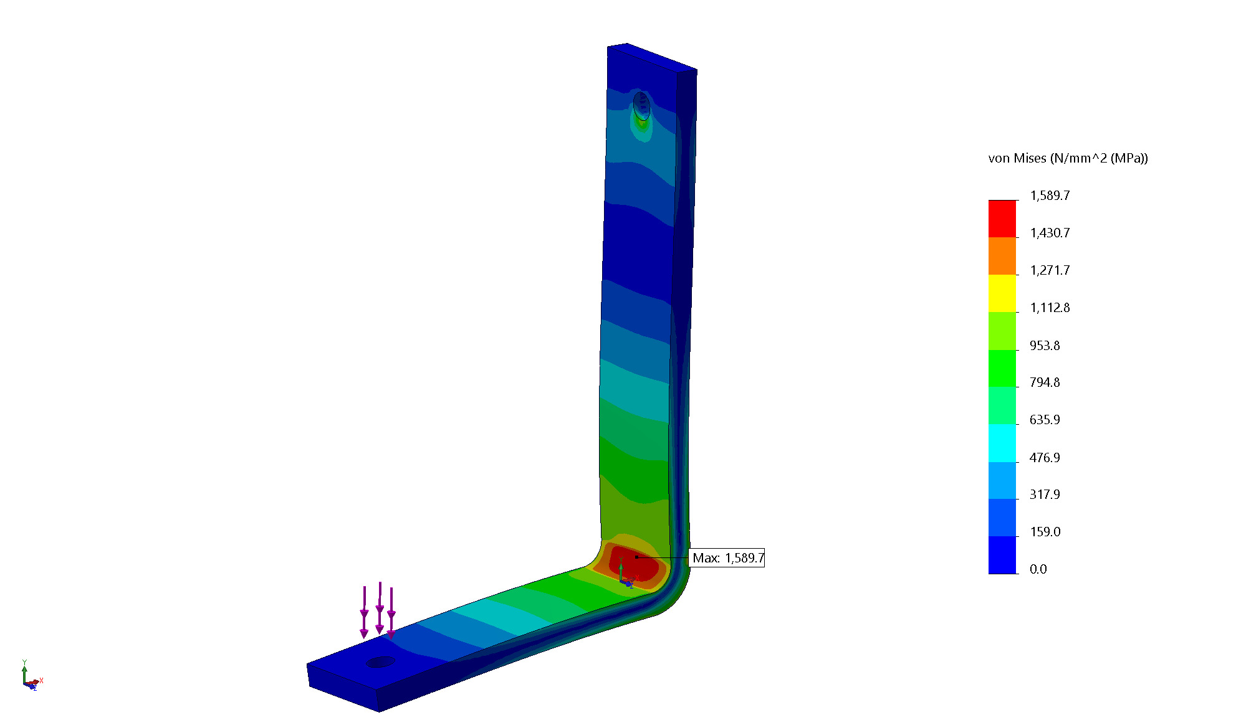

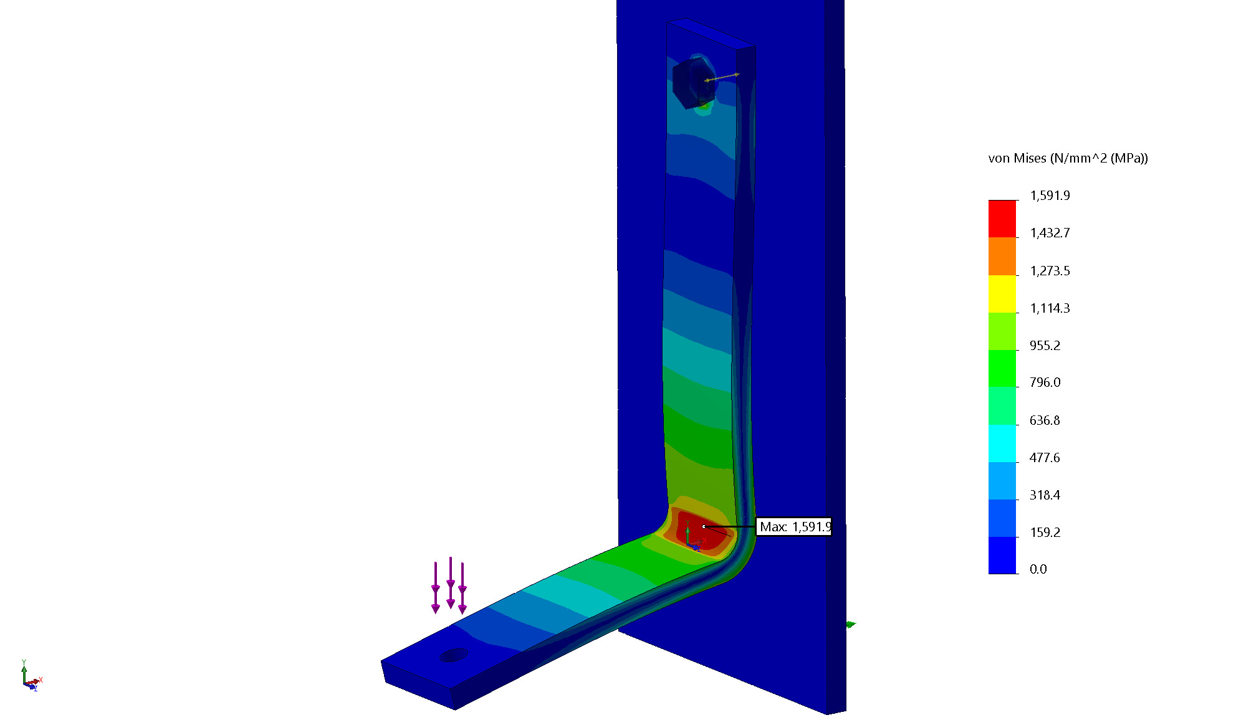

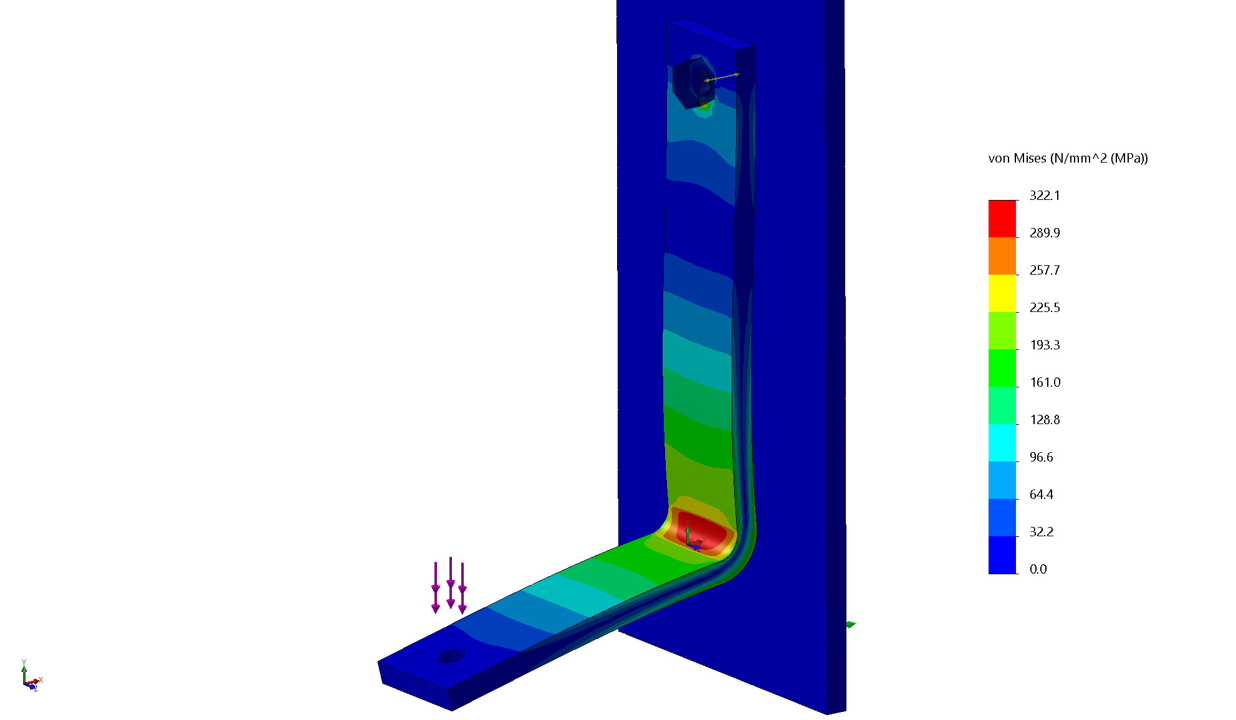

The Holy Grail is a cup and is generally accepted as mythic, but some believe it is more than just a figment of medieval literature. Some believe the holy grail provides eternal youth, can heal all wounds and grant everlasting happiness. The Holy Grail is often used to describe something that is sought after and very hard to attain. My first thought was, if I found everlasting youth, I could be doing FEA for an eternity, so that put me off a bit. But maybe there are different types of Holy Grails? Then I thought, what about pursuing the Holy Grail of FEA? I’m not sure what that would be but the only thing that springs to mind would be to pursue the ‘Perfect FEA Model’. There was a rumour once upon a time, that an FEA analyst in Outer Mongolia achieved the impossible and found the Holy Grail of FEA in the form of a ‘Perfect FEA Model’. Unfortunately, so the story goes, his project was cancelled due to cutbacks and the ‘Perfect FEA Model’ was filed somewhere, never to be found again. Who needs that guy’s model anyway, I’ll do my own. How hard can it be? To complete this quest, I thought I would start with something simple like a bracket with a load on it. I would run the model as a single part with constraints and a load. Maybe then I could find the ‘Perfect FEA Model’? I’ll give it a try. I used the same bracket example from other parts of the FEA Tutorial that is on the Value Design Ltd website. It is basically just an L-shaped bracket with a hole fixing on one end and a load on the other end as shown below. I started my quest by doing a linear static analysis of the orange bracket only, fixing the hole, and applying a load. I also constrained the line on the radius where it contacts the green plate in X direction only. I refined the mesh just enough, trust me I’m a stress engineer 😊, ran the model and recorded the stress as follows; But that’s not a ‘Perfect FEA Model’, I hear you say. You’re right, it’s far from perfect. For a start there is no contact, the bolt isn’t even in the model so how could it be perfect? I’ll try again but this time with all the bells and whistles. I then built another model but this time included the green plate as well, defined contacts and put a bolt in with a preload of 41.9 KN for an M12 coarse threaded Grade 8.8 bolt. The results are shown below; Could this be the perfect FEA model? Wait, a minute…. I’ve just been told that the bolt preload is wrong, it should be 44.1 KN, not 41.9 KN. Oh, and someone said, it’s a countersunk screw, not a bolt in any case. A co-worker just pointed out that I put in a coefficient of friction value of zero for the contacts and he said it should be 0.1. Then another joined in and said it should be 0.3. One more thing, the von Mises stress is about 1600 MPa and the yield stress for S355 steel is 355 MPa, so all of the stress values in my model are wrong. Damn you FEA! OK fair enough, I could put nonlinear materials in it to find the real stress. I just need a stress-strain curve that exactly matches my bracket material. It needs to be a perfect match otherwise my FEA model cannot possibly be perfect and I will have failed in my quest. Ten minutes of Google searching later…… OK, I have found some stress-strain curves but they all seem to be slightly different. Then I had another idea. I will reduce the load and this will reduce stress to less than yield, then I can finally claim I made the ‘Perfect FEA model’. I’ll try again, this time with a load of 1500 N. Maybe I have just found the Holy Grail of FEA!

Then a few thoughts crossed my mind.

My model can’t possibly be perfect and there’s no way I can claim it is the Holy Grail of FEA. Sigh. Mmmmmmmm……maybe Google can help? I typed in a Google search. Who is that bloke from Outer Mongolia who found the Holy Grail of FEA in the form of a ‘Perfect FEA Model’? Nothing came up in the search results, was it even true or just a myth? I never did find the Holy Grail of FEA, but I have to believe it exists. Maybe somewhere out there, in a land far away, there is a little model. A little FEA model that is just perfect in every way. Can you find the Holy Grail of FEA?

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

AuthorChris Hall Categories

All

Archives

May 2023

|

- Value Design Ltd

- Services

- Projects

-

Finite Element Analysis

- Introduction to Basic FEA

- Units

- Co-ordinate Systems

- FEA Procedure

- Defining Objectives

- Stress Concentration

- Geometry import / clean up

- Meshing

- Material Properties

- Boundary Conditions

- Solvers

- Investigating FEA Results

- Reporting

- Stress Theories

- Cantilever Beam Worked Example

- Pressure Vessel Worked Example

- Shaft in Torsion Worked Example

- Buckling Worked Example

- Bearing (Contact) Worked Example

- Non Linear Material Worked Example

- Portal Frame Worked Example

- BLOG

- FAQ

- CONTACT