- Value Design Ltd

- Services

- Projects

-

Finite Element Analysis

- Introduction to Basic FEA

- Units

- Co-ordinate Systems

- FEA Procedure

- Defining Objectives

- Stress Concentration

- Geometry import / clean up

- Meshing

- Material Properties

- Boundary Conditions

- Solvers

- Investigating FEA Results

- Reporting

- Stress Theories

- Cantilever Beam Worked Example

- Pressure Vessel Worked Example

- Shaft in Torsion Worked Example

- Buckling Worked Example

- Bearing (Contact) Worked Example

- Non Linear Material Worked Example

- Portal Frame Worked Example

- BLOG

- FAQ

- CONTACT

Engineering Services

Our Core Values

- Pragmatism. Adopting a pragmatic approach and offering down to earth and practical solutions.

- Honesty and integrity. We don’t claim to be experts at everything and we focus on what we’re good at and how we can help you.

- Adding value. Reducing manufacturing costs and shortening lead times add value. Validating designs to improve products add value. Adding value is what we do, that’s why we’re called Value Design Ltd.

Contact us to find out how we can contribute to your success.

We have a wealth of experience with advanced finite element analysis and some examples of the type of services we offer are as follows;

Nonlinear Finite Element Analysis for Permanent Deformation

Some components are designed to go beyond yield and permanently deform. Others are designed to reach plasticity in some areas to protect other areas such as bolted or welded connections for extreme loading. Sometimes we just need to know what will happen if the components are severely overloaded. Will it drop the payload, how much force can it handle before it fails?. Only nonlinear FEA or physical testing can provide the answers to these questions.

Impact Forces Due to Collisions and Drop Tests

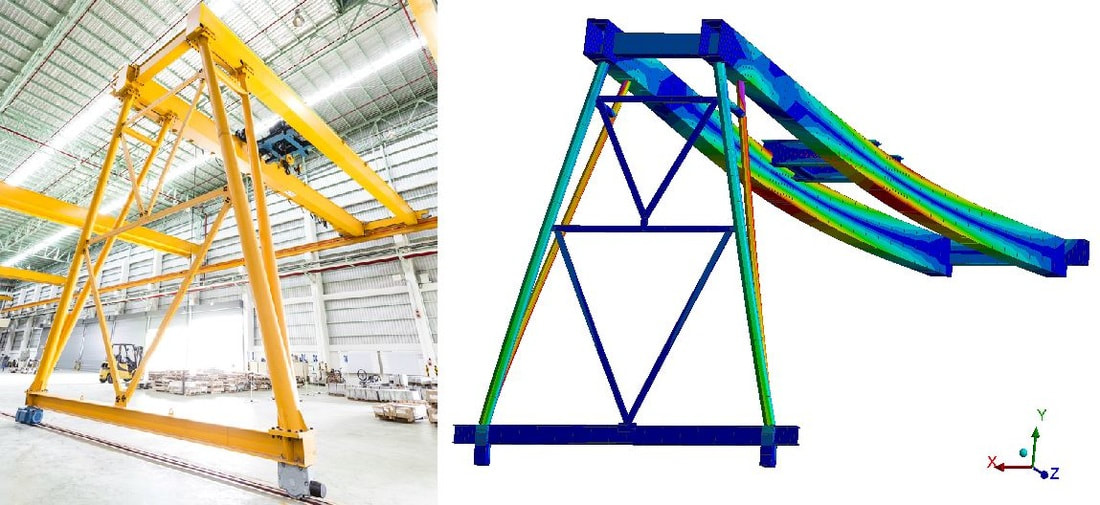

There are many reasons we need to find accelerations, impact forces and the stress levels when a product or machine collides with an object or is dropped. Examples include high integrity trolley impacts in nuclear facilities, gantry cranes hitting the buffer stops or products being dropped.

Response Spectrum and Harmonic Analysis for Vibrations

Large structures in some parts of the world must be designed to withstand earthquakes, this is where Response Spectrum Analysis is required. Silos, hoppers and other machinery can have vibrators fitted to clear blockages or other sources of vibration that could induce fatigue failures and this is where Harmonic Response Analysis can be employed.

Structural Steel Fabrications for Design Code Assessment

Steel structures and large machinery often requires design code compliance assessment for safety and CE marking. This is where finite element analysis can be undertaken to assess load cases such as wind, snow/ice, permanent and variable loading according to Eurocodes or others such as BS EN 13001, BS EN 13155 to name a few.

Engineering Analysis Services

We provide accurate and reliable finite element analysis reports on a range of products using industry leading technology.

- Design Optimisation

- Weight Reduction

- Design Recommendations

- ‘What If’ Studies

- Material Selection

- Manufacturing Process

- Failure Diagnostics

- Concept Designs

- Test Rig Correlation

Design Code Assessment Services

We regularly provide technical documentation and calculations to demonstrate compliance with the design codes and standards.

- Eurocodes Assessment

- ASME Code Assessment

- British Standards Code Assessment

- Pressure Vessel Assessment

- Factors of Safety

3D CAD Services

Complete CAD and draughting services for prototypes through to final production.

- Value Design Ltd

- Services

- Projects

-

Finite Element Analysis

- Introduction to Basic FEA

- Units

- Co-ordinate Systems

- FEA Procedure

- Defining Objectives

- Stress Concentration

- Geometry import / clean up

- Meshing

- Material Properties

- Boundary Conditions

- Solvers

- Investigating FEA Results

- Reporting

- Stress Theories

- Cantilever Beam Worked Example

- Pressure Vessel Worked Example

- Shaft in Torsion Worked Example

- Buckling Worked Example

- Bearing (Contact) Worked Example

- Non Linear Material Worked Example

- Portal Frame Worked Example

- BLOG

- FAQ

- CONTACT